Hydraulic methods are broadly utilized in numerous industries on account of their effectivity and reliability. From heavy equipment to easy instruments, hydraulic methods have grow to be an important a part of many operations. Nevertheless, the efficiency of those methods may be compromised if the suitable hydraulic merchandise usually are not chosen or if they don’t seem to be maintained correctly.

On this article, we are going to talk about the important hydraulics merchandise that you just want for optimum effectivity. We are going to cowl the center of your system: hydraulic pumps, how to decide on the proper valves in your wants, and why filters and hoses matter. Moreover, we are going to present upkeep ideas to make sure most effectivity out of your hydraulic system. By understanding these important elements and their significance in sustaining an environment friendly hydraulic system, you’ll be able to enhance your operations’ productiveness whereas decreasing downtime and upkeep prices.

Hydraulic Pumps: The Coronary heart of Your System

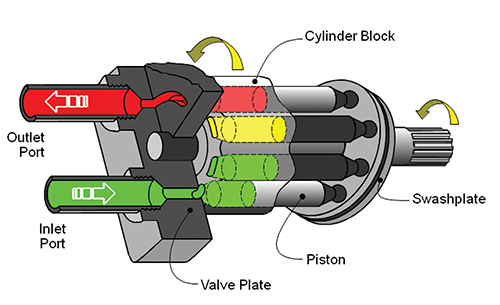

The hydraulic pump serves because the central element of the system, functioning as its coronary heart and offering a important supply of energy to allow the graceful operation of equipment. Hydraulic pumps come in numerous varieties, resembling gear pumps, vane pumps, and piston pumps. Gear pumps are recognized for his or her simplicity and low price, whereas vane pumps supply increased efficiency than gear pumps on account of their larger effectivity in dealing with viscous fluids. Piston pumps are extra advanced however present higher sturdiness and management over movement charges.

To make sure that your hydraulic pump operates optimally, common upkeep is important. This consists of checking for leaks or harm to seals, filters, and valves. It is usually important to watch fluid ranges commonly since insufficient fluid may cause cavitation contained in the pump resulting in failure or harm of inside elements. In case of any malfunctioning or failure of the pump, troubleshooting ideas embody checking for broken components like worn-out bearings or clogged filters that will have an effect on its efficiency. Correct upkeep procedures not solely lengthen the lifespan of your hydraulic pump but in addition helps stop pricey repairs or replacements down the road.

Selecting the Proper Valves for Your Wants

Choosing applicable valves is crucial for attaining most productiveness and making certain the graceful operation of your hydraulic system. Valve choice standards should be thought of when choosing the proper valve in your wants. These embody movement fee, strain ranking, working temperature vary, compatibility with fluid varieties, and application-specific necessities resembling noise discount or area limitations. Frequent valve varieties and their makes use of are additionally necessary to know when making a choice.

The commonest sorts of valves utilized in hydraulic methods are ball valves, verify valves, reduction valves, directional management valves, and movement management valves. Ball valves are perfect for on/off purposes in high-pressure environments. Test valves stop reverse movement within the system whereas reduction valves defend towards overpressure conditions. Directional management valves handle the path of fluid movement inside the system whereas movement management valves regulate the fluid’s velocity or quantity via a particular level within the system. Choosing the proper sort of valve will depend upon its meant use inside your hydraulic system and the way it can meet all needed standards for optimum effectivity.

Filters and Hoses: Why They Matter

Filters and hoses are indispensable elements of any hydraulic system, as they play a significant function in making certain the purity and integrity of the fluid medium that powers the equipment. The significance of cleanliness can’t be overstated in terms of hydraulic methods. Contamination may cause important harm to elements resembling valves, pumps, and cylinders, resulting in pricey repairs or replacements. Filters assist stop contamination by trapping particles resembling filth, particles, and steel shavings that will enter the system via put on or different sources. Additionally they assist preserve constant strain ranges by stopping blockages attributable to contaminants.

The longevity of hoses is one other essential consider sustaining optimum effectivity in hydraulic methods. Hoses switch fluid below excessive strain from one element to a different, making them topic to excessive stress over time. As hoses degrade or fail on account of age or harm, leaks can happen that compromise the system’s efficiency and improve the chance of injury or damage. Common inspection and alternative of hoses are important for avoiding these issues. Selecting high-quality hoses created from sturdy supplies and rated for particular purposes can be important for minimizing downtime and maximizing effectivity in hydraulic methods.

Upkeep Ideas for Most Effectivity

Upkeep practices are important for sustaining the efficiency and reliability of hydraulic methods. Prevention measures resembling common inspections, testing, and filter replacements can assist stop system failures or breakdowns that will result in costly repairs or replacements. Well timed troubleshooting methods additionally play a big function in sustaining optimum effectivity. Figuring out small points earlier than they escalate into larger issues is an efficient option to decrease downtime and maximize productiveness.

It’s beneficial that common inspection intervals be established primarily based on elements resembling machine utilization, environmental circumstances, and producer suggestions. Throughout these inspections, technicians ought to verify for indicators of wear and tear and tear on hoses, fittings, seals, and filters. Changing worn-out hoses and filters with high-quality options will assist preserve most effectivity by making certain that the system operates at peak efficiency ranges. It’s additionally necessary to make use of suitable components when changing elements to keep away from incompatibility points which may lead to decreased effectivity and even harm to all the system.

Incessantly Requested Questions

1. What are the frequent causes of hydraulic pump failure?

Hydraulic pump failure may be attributable to quite a lot of elements, starting from easy points resembling low fluid ranges and soiled filters to extra advanced issues like worn-out bearings and damaged shafts. One efficient option to stop pump failure is thru common preventative upkeep, which includes conducting periodic inspections and changing components which have reached the tip of their helpful life.

Troubleshooting methods can be used to establish potential points earlier than they result in pump failure. This consists of monitoring strain ranges, checking for leaks, and listening for uncommon noises throughout operation. By taking a proactive method towards figuring out and addressing potential issues, hydraulic system operators can be sure that their pumps function effectively and reliably over the long run.

2. How do you establish the suitable valve dimension in your hydraulic system?

Sizing concerns and valve choice standards are essential elements in figuring out the suitable valve dimension for a hydraulic system. Numerous parameters resembling movement fee, strain drop, fluid viscosity, and temperature needs to be taken under consideration earlier than making the ultimate choice. The valve dimension needs to be chosen in keeping with the utmost movement fee required by the system to make sure that it operates effectively with out experiencing any backpressure or cavitation points.

Moreover, choosing a valve with an applicable Cv worth can be important because it determines its capability to regulate movement successfully. Different elements resembling area constraints, price range limitations, and compatibility with different elements of the hydraulic system additionally should be thought of whereas choosing the proper valve dimension for optimum efficiency.

3. Are you able to combine and match completely different manufacturers of hydraulic hoses and filters?

Hydraulic fittings compatibility is crucial for the right functioning of a hydraulic system. Mixing and matching completely different manufacturers of hydraulic hoses and filters can result in incompatibility points, which may end up in leakage, strain drops, and even system failure. Subsequently, it’s best observe to pick hoses and filters from the identical producer or be sure that they’re suitable with one another via rigorous testing.

Factors resembling strain ranking, temperature vary, chemical resistance, and hose building needs to be thought of when choosing hydraulic hoses and filters. Moreover, common inspection and upkeep of the hydraulic system can assist establish any potential compatibility points early on earlier than they trigger important harm.

4. What are the implications of not performing common upkeep in your hydraulic system?

Common upkeep is essential for the optimum efficiency and effectivity of hydraulic methods. Neglecting to conduct common upkeep can have important penalties on the system’s general performance, resulting in decreased effectivity and elevated downtime. The significance of upkeep can’t be overstated, because it ensures that every one elements are working accurately and that any potential points are caught earlier than they grow to be main issues.

A scarcity of correct upkeep may end up in a build-up of contaminants, resembling filth and particles, which might clog filters and scale back oil movement. This may result in extreme put on on elements, leading to untimely failure or breakdowns. Insufficient lubrication on account of soiled oil may trigger frictional losses that lower effectivity over time. In the end, neglecting common upkeep will impression the general effectivity of your hydraulic system negatively.

5. Is it needed to make use of specialised hydraulic fluids, or can you employ different sorts of oil?

Picture supply: .designworldonline.com

Using specialised hydraulic fluids is important for the optimum efficiency and longevity of a hydraulic system. Artificial fluids, particularly, supply a number of advantages over standard mineral-based oils. They’ve increased resistance to oxidation, which prevents the formation of sludge and polish that may clog filters and scale back effectivity.

Moreover, they supply superior low-temperature efficiency, making certain clean operation even in chilly environments. When choosing a hydraulic fluid, it’s important to contemplate its compatibility with completely different supplies used within the system resembling seals and hoses. Incompatible fluids may cause degradation or failure of those elements resulting in pricey repairs. Subsequently, utilizing applicable hydraulic fluids is essential for the environment friendly and trouble-free operation of hydraulic methods.

Conclusion

Hydraulic methods are just like the circulatory system of your equipment, with the hydraulic pump being the center. Valves act as arteries, and filters and hoses operate as veins, all working collectively to make sure optimum effectivity. Identical to sustaining a wholesome coronary heart is essential for general well being, choosing applicable pumps and valves in your hydraulic system is essential for its efficiency.

Choosing the proper values may be likened to selecting a wholesome way of life. A balanced weight-reduction plan of various vitamins offers our our bodies with what they should operate correctly. Equally, choosing valves that match your particular wants will assist hold your hydraulic system operating easily. Filters and hoses act as cleaning brokers in our allegory; simply as veins carry impure blood towards the center to be cleansed by the lungs or kidneys, so do filters take away contaminants from hydraulic oil earlier than it reaches the pump.

In conclusion, sustaining environment friendly hydraulic methods requires consideration to element when choosing elements resembling pumps and valves whereas making certain clear oil movement via common upkeep of filters and hoses. Utilizing this allegory can assist emphasize how important every element is in holding your equipment working at peak efficiency. So deal with your “circulatory” system by choosing high quality hydraulics merchandise at this time!